Cloud Based BIM Construction Execution Support

We are experts in creating construction 3D Models from hand sketches, 2D drawings, or 3D Engineering Models created by traditional engineering firms. What Engineering firms do not want you to know is that the 3D Models they create rarely agree with the Drawings Issued For Construction. This is because the designers “Fake” the Model which means they provide just enough detail to meet the requirements for Model Review session but the model is missing the accuracy and details required for construction. One of the reasons this happened frequently is because engineering firms pride themselves on executing projects that same way over and over. The cultures and work environment drives the same results. Creating engineering drawings. These habits and process are difficult to change. Even more of a problem is when your business is to bill manhours, there is NO incentive to change.

Our construction 3D Models are virtually created for ONE purpose. To procure, fabricate, track and erect build off of the model (NO drawings required). We provide services which develop plans and work packages from the single 3D Model. We help support construction by providing prioritized data at the optimal time needed and sequence steps for field installation. Construction work is planned accurately based on materials received and resources available. Visualizing the work to be performed identifies constraints and reduces risk for safety and productivity.

We begin the process by optimizing materials. Most Bill of Materials created by engineering firms lack enough information and detail to be purchased and tracked. Our construction models converts the bill of materials into a complete description with unique identification in effect eliminating substitutions.

Our Construction Modelling support follows from field installation through system turnover. Work packages are automatically created in a fraction of the time required to create traditional packages. Using the 3D Model, cost and schedules are tracked and reported by automatically tabulating quantities and labor hours versus actual values.

Our Benefits include:

Ability to develop and sequence construction activities using virtual construction simulation tools.

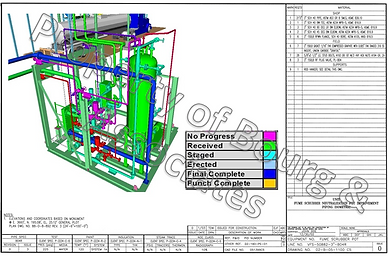

Ability to see progress and status using augmented reality tools. These tools allow the execution team to visualize the status of material availability, work remaining, installation status, turnover status, or any other condition using the virtual construction model.

Ability to plan ahead. Using the single 3D Model, we ensure materials are on site and crafts are available before work is scheduled.

Savings. A significant amount of resource time is reduced by automating work packages. We easily create, manage, edit, and distribute construction work packages by leveraging the most up-to-date project information, construction progress, and material status.

Early Detection. Performing continuous constructability reviews which identify change orders and reduce delays.

Simulate Construction Scheduling sequencing. We examine construction activities by connecting project schedules and virtual construction models allowing visualizations to better understand sequencing to avoid costly errors. With a clear understanding of the construction path, our support team can create solutions to maximize safety while meeting schedule requirements.

A Single Data Base. The 3D Model is just a graphical representation of the data base which includes any document which needs to be attached to a field item.

Color Coded Results. Status of work, type of work (insulation vs. non-insulation, hydro vs. radiograph, scaffold requirements, vessel entry, and safety precautions) are viewed clearly with color coded indicators. The visualization of colors produces a better method of communication down to the installation detailed level.

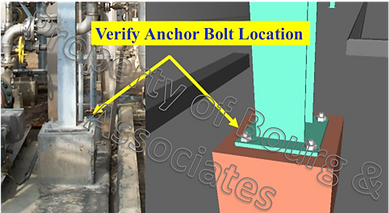

In addition, Our Virtual Construction Support Services include using our scene capture technology tools to verify anchor bolt locations for steel and equipment PRIOR to pouring the concrete. Having the ability to know and correct if the equipment or reference steel is in the wrong location, prevents all the piping associated with that piece of equipment from having to be modified as a result of a bust. Our user friendly 3D field survey tools also are used to establish baselines using survey nails with true 3D Coordinates which provide a square reference plane for the contractor to pull their dimensions.

Please contact us at sales@az-built.com for more information or a proposal on our Virtual Construction Support Services.